How can large volumes of hydrogen be stored in the future? The best way is underground, experts say. Components from Freudenberg Oil & Gas Technologies have made it possible to analyze and convert a salt cavern in the Netherlands.

Thanks to technological aids, many medical operations are minimally invasive today using the so-called keyhole approach. Something equivalent is happening in Zuidwending, near Groningen in the Netherlands. In this case, the “patient” is 1,200 meters below the surface of the earth.

Shaped like a huge cigar pointed downward, it is as long as the Eiffel Tower and has similar external dimensions. It is also a hollow space, namely a salt cavern, that is expected to hold about 6,000 tons of hydrogen. That is equivalent to 200 gigawatt hours of energy, or enough to fill up about 86,000 trucks equipped with fuel cells from Freudenberg e-Power Systems.

Salt caverns are mainly artificially created, underground hollow spaces. They result from the drilling and de-brining of salt domes. Large numbers of caverns are already used to store crude oil and natural gas. The salt structures create a natural seal and hardly react at all with the gas stored there. Based on the current level of technology, they can also hold large volumes of hydrogen – especially in Europe where the caverns can be found in large numbers. The conversion from natural gas to hydrogen is being tested in Zuidwending.

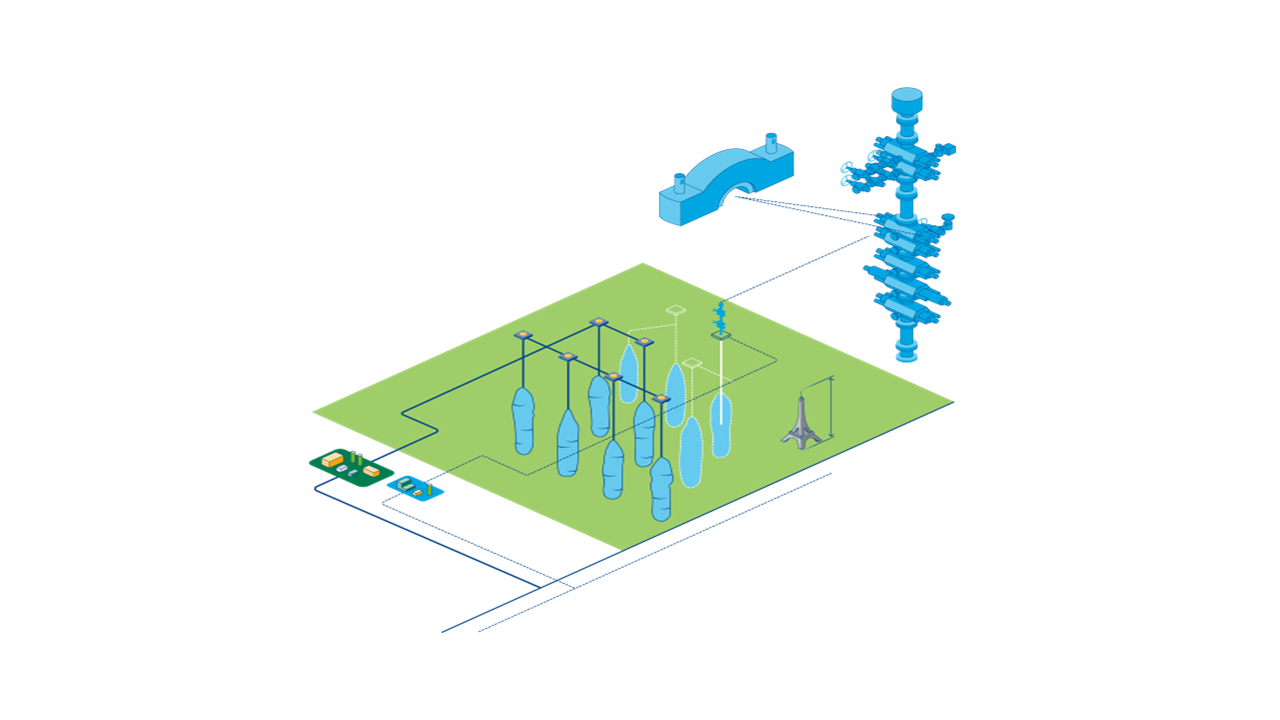

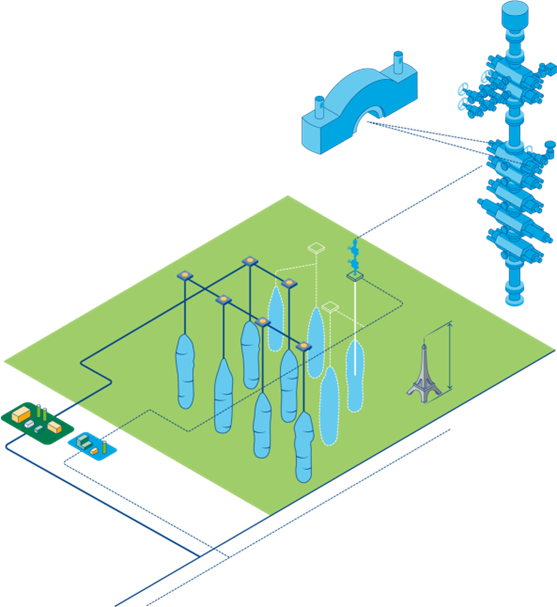

HyStock, a unit of the state-owned grid operator Gasunie, is running tests on the industrial storage of hydrogen using components from Freudenberg Oil & Gas Technologies (FOGT). A total of 14 so-called pipe packers and stripper packers were used in the 9-meter structure above the roughly 30-centimeter bore hole. “The opening is just a keyhole compared to the dimensions underground,” said Oliver Lips, Manager, North Sea & Europe at FOGT. “But that’s not a special aspect – it’s normal in our industry.”

Two pipe packers or two stripper packers are installed in each of the seven so-called U-type blowout preventers (BOP).

The BOP stack structure for the conversion is 9 meters high.

Testing, testing, testing

In Zuidwending, HyStock is testing the effect of hydrogen on equipment, materials and cement, along with the salt wall overlaid with it. Experts take samples to see whether the cavern is maintaining the high quality of the hydrogen – and to what extent they have to adopt methods and testing devices that are different from those used for natural gas, which had been stored there previously. For example, it is important for the barrier systems to remain firmly closed under pressure since hydrogen atoms are the tiniest known to science. Its molecules need very little space to penetrate materials. “Our packers naturally had to meet the application’s core requirement from WellGear, a long-time customer,” Lips said.

Freudenberg components provide the highest level of safety

WellGear, a leading provider of well interventions and decommissioning services, was responsible for extending the tubing string as the drill hole was filled and pressurized with hydrogen – a technique known as snubbing. Two pipe packers and two stripper packers enclosed the pipe mechanically and thoroughly blocked the hydrogen from escaping the tube. An integrated cutting tool was used in one component. It made it possible to cut through the tubing in an emergency. “It has been an exciting project. We were able to carry it out with maximum safety with the help of Freudenberg and the components it provided. It was probably the first-ever snubbing involving hydrogen, too,” said Sven Heijwegen, WellGear’s Chief Operating Officer.

When the storage of industrial hydrogen is launched at the site at the end of 2026, FOGT will have made an important contribution.

Oliver Lips, Manager, North Sea & Europe, FOGT

Operation completed

The cavern has now been successfully converted. During the current phase of the project, more research, including an investigation into microbiological reactions, is being undertaken using the conventional inflow and outflow system. “As far as wear goes, our components have proven themselves in this application. Our subsequent material tests have shown this,” said Lips. “When the storage of industrial hydrogen is launched in Zuidwending at the end of 2026, FOGT will have made an important contribution to the project.”

Oliver Lips, Manager, North Sea & Europe at Freudenberg Oil & Gas Technologies (FOGT)

Lips specialized in sealing technology at various companies after completing his studies in business administration in 2002. He has been employed at FOGT since 2013 and has been in charge of its facility in Aberdeen, Scotland since 2018, focusing on the North Sea region. He likes to ski and is an avid amateur cook who enjoys cooking either in the oven or on the grill.

Numbers, data, facts

- 1,200 meters: That’s how far down the salt cavern lies.

- 6,000 tons of hydrogen: That’s how much it can hold.

- 86,000 trucks equipped with fuel cells from Freudenberg e-Power Systems: That’s how many vehicles the volume of hydrogen can fill up.

- 14 pipe and stripper packers from FOGT were used.

- In 2026, the industrial storage of hydrogen is scheduled to begin.