From a tannery to an innovative technology group

Freudenberg lives from innovation, just as it has for over 170 years. What began at the time with leather is today a broad range of products for thousands of applications: From solutions for the automotive industry to products for wind turbines and innovative cleaning technologies. The company currently invests more than 500 million euros annually in research and development to bring new solutions to the market. Freudenberg has always benefited from two key advantages: Material competence and the willingness to embrace change. And despite the many years of progress and technological change, leather still plays a role in the company’s products today.

Patent leather – the first new product innovation in the year 1850 – becomes the first major driver of the company’s development. Thanks to the patent leather business, the company grows into one of the largest leather producers in Germany by the mid-1870s. When the chrome tanning process is first introduced starting around 1900, Freudenberg becomes the leading leather producer in Europe and one of the largest in the world – and then holds this position until the end of the 1920s. At this point, the company shifts the focus of its product portfolio as the global economic crisis triggers a collapse in the leather market. New sales sectors must be found. Otherwise, the company will be forced to lay off hundreds of workers.

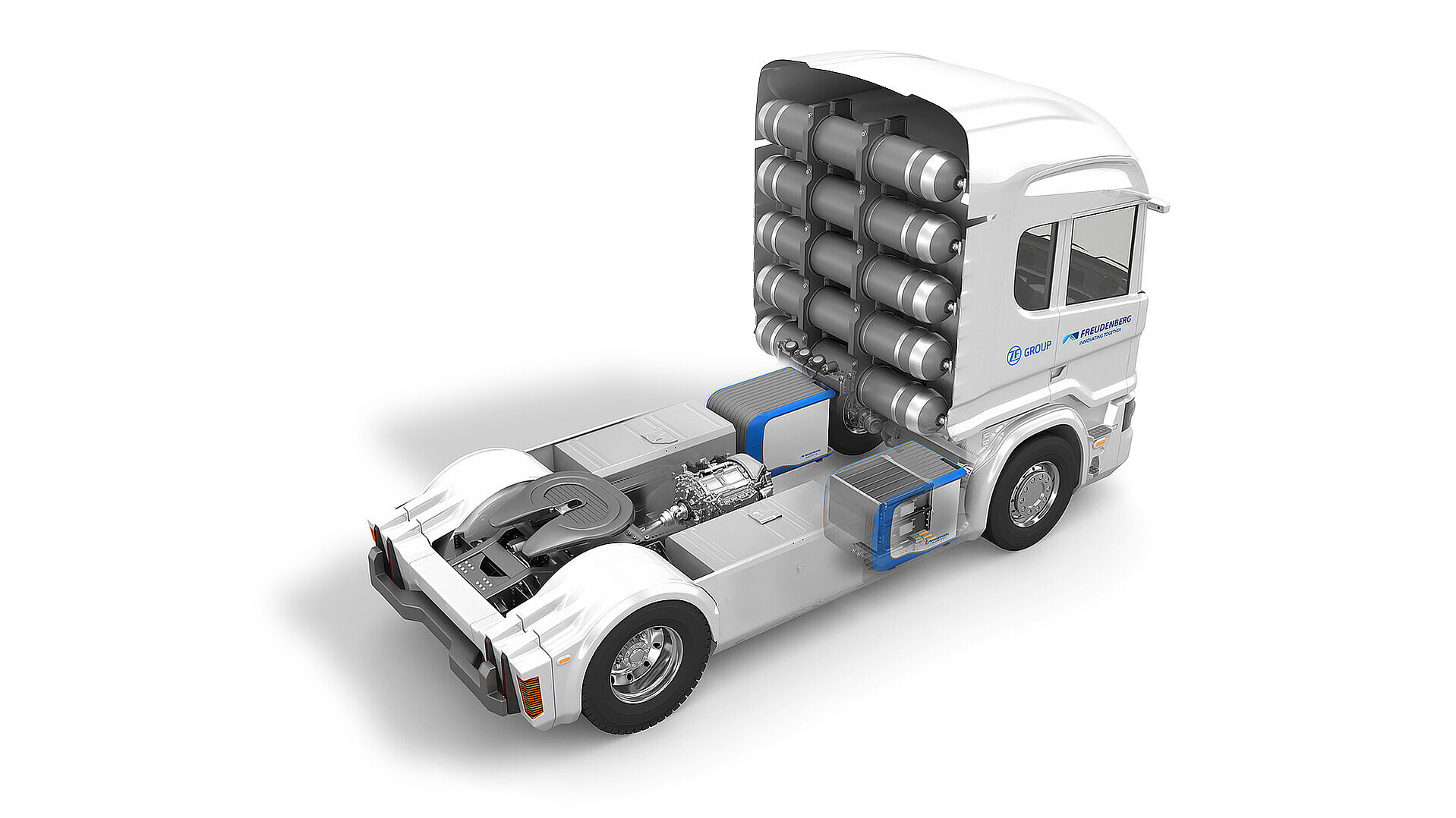

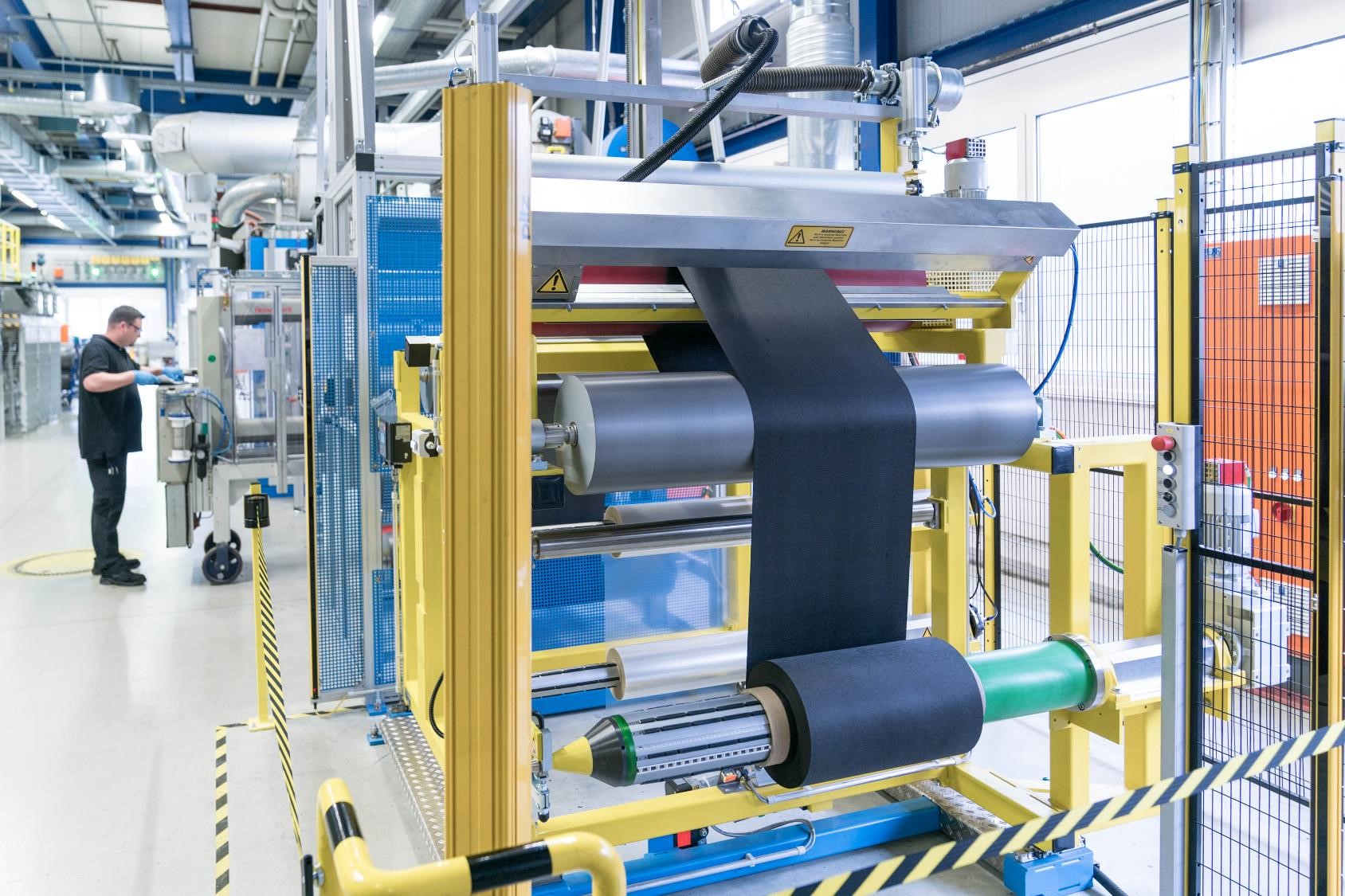

Freudenberg produces Gas diffusion layers, one of the performance critical components in fuel cells

“Change to succeed”

New ideas are called for that will allow Freudenberg to weather the changed conditions. The research and development process that went into traditional leather production is a perfect example of Freudenberg’s ability to develop useful products and utilize its know-how at precisely the point it is most needed. Even though the leather production was shut down 20 years ago, leather still lives on in today’s product portfolio. A full three of Freudenberg’s business areas have their roots in the traditional leather business: Seals and vibration control technology, technical textiles and filtration, and cleaning technologies and products.

Starting in 1929, Freudenberg develops from a traditional leather factory into a maker of leather seals. This innovation marks the start of the company’s involvement with seals and vibration control technology. The diversification of the company begins with the production of these seals for the automotive industry.

Seven years later, the leather seals are successively replaced by elastomeric materials. The elastomer competence of Freudenberg is continuously expanded, leading to today’s large range of high-performance elastomer seals for diverse and highly challenging technical applications. “Today, seal manufacturing constitutes an entire branch of the company – Freudenberg Sealing Technologies,” explains Michael Horchler, archivist and company historian.

Today, seal manufacturing constitutes an entire branch of the company – Freudenberg Sealing Technologies

Dr. Michael Horchler

The beginnings of the business areas technical textiles and filtration as well as cleaning technologies and products can also be traced to initial steps to diversify the leather production. This begins in the mid-1930s, when Freudenberg develops a synthetic leather from latex. A nonwoven carrier material is used to produce this leather replacement. At the end of the 1940s, the nonwovens were then further developed into new products. This leads to interlinings for the clothing industry and cleaning cloths of the brand Vileda, which are also made from nonwovens. Next, the nonwoven range is expanded to include technical applications, such as filters. Thus runs the course of the original business area of leather. The new areas eventually fully split off from the traditional core business and are now key pillars in the portfolio of the Freudenberg Group.

Success through continuous research and development

The technology company invests heavily in research and development to improve existing products and adjust the portfolio to keep pace with changes in the various sectors – especially when it comes to more efficient future mobility. One current topic of great importance is fuel cell technology, which has a critical part to play in a successful energy transition. With over 25 years of experience in this area, Freudenberg enjoys a unique level of vertical integration, putting the company in a position to help shape the development of an entire industry. Freudenberg is developing hydrogen-compatible materials and components such as filters, seals and gas diffusion systems and now even builds entire fuel cell systems.