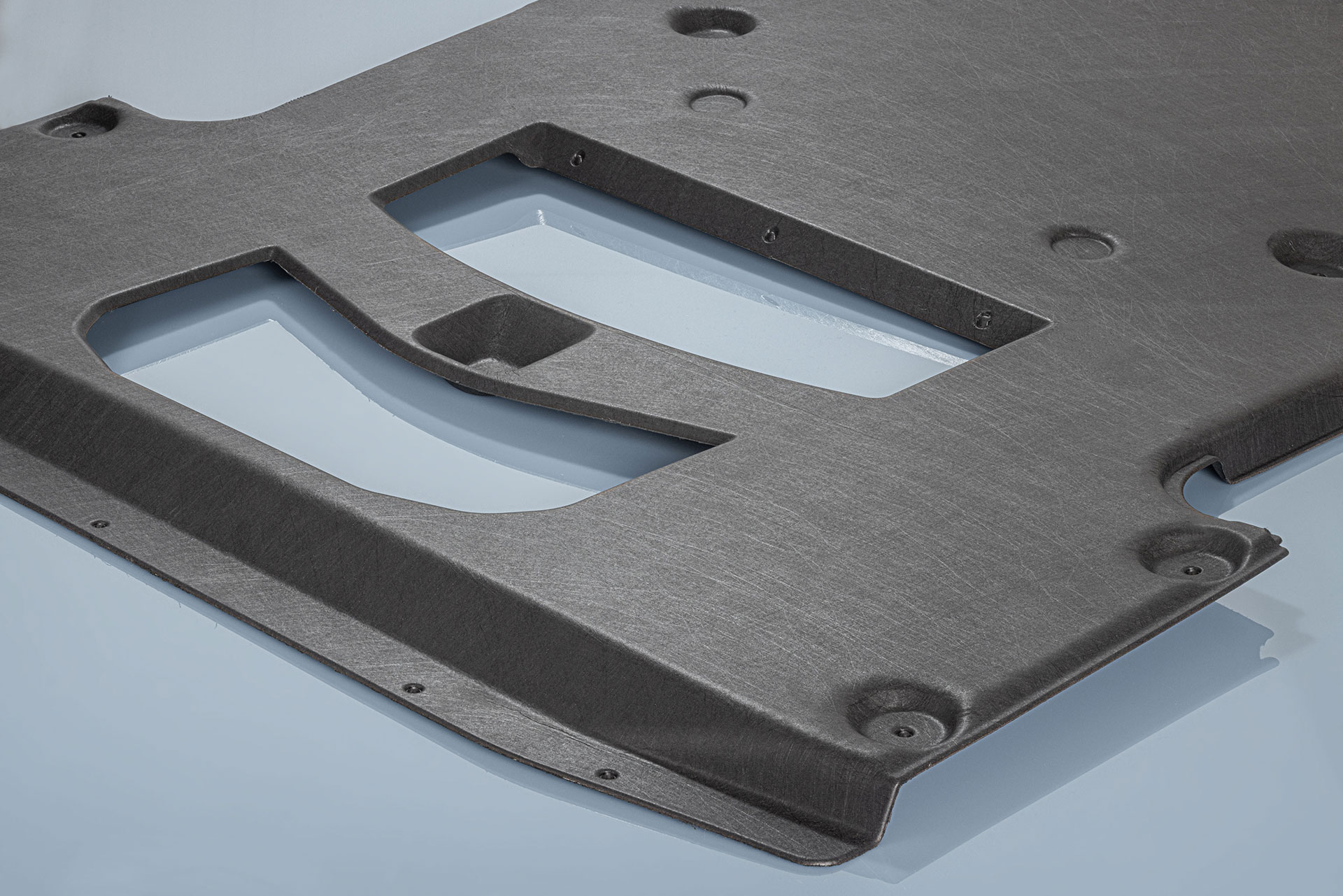

Did you know? Cars are made up of about 30,000 components on average. Many of them are tiny or go unnoticed, but play a major role. One such component: the underbody shield. It protects cars from the many effects of the environment. Freudenberg Performance Materials produces a high-tech material from an innovative combination of staple fiber and spunbond nonwovens, helping make for lighter automobiles. Known as the underbody shield, its main feature is not only its low weight, but that it is designed to be sustainable – all the way from production to the end of its service life.

Sustainable from the start – with a view to the future

The combination of the two materials provides greater stiffness and better quality properties than competing products made of pure staple fibers, and offers greater water repellency through the lotus effect. “This enables the exterior product to provide cars with better protection from environmental influences,” explains Arun Venugopal, Strategic R&D Manager at Freudenberg Performance Materials. The underbody shield also boasts an impressively low weight: It is up to 25 percent lighter than conventional underbody panels, reducing vehicle weight and thus CO2 emissions.

The staple fiber is already up to 50 percent recycled when it is made into underbody panels. “Our aim is to increase the content of recycled staple fiber to 80 percent,” Venugopal said. And there are more ambitious goals for the future: In the future, 100 percent of the waste generated in production at Freudenberg Performance Materials and the automotive supplier will be recycled, so it will flow back into new underbody shields or other nonwovens for automotive or non-automotive use in later production runs. “If suitable conditions are established at the automotive manufacturers, it would even be possible to take back the underbody shield after end of life, i.e. after about 15 years of use in the vehicle, recycle it and use it for new applications,” explains Venugopal.

Our aim is to increase the content of recycled staple fiber to 80 percent.

Arun Venugopal, Strategic R&D Manager at Freudenberg Performance Materials

Lightweight and sustainable

The underbody shield from Freudenberg Performance Materials is currently being sampled by various automotive manufacturers or is already going through actual trials. “Our underbody is expected to be on the roads starting in 2023. It still has complicated tests to pass by then,” says Venugopal, explaining the process. After all, exterior components of cars have a lot to hold up to, and are tested for the effects of forces such as stone chips, water and wind.

The market offers great potential: 70 million square meters of underbody protection in total is already on the road in cars in Europe alone. While Freudenberg Performance Materials is currently developing and marketing the underbody shield in Europe, the product will also be available in other regions of the world in the future. Is there any potential for further applications? Structural parts expert Venugopal says there is: “Just recently we provided a customer with a sample for a trunk lid. Our goal is to develop more sustainable products for automobiles and replace more applications with fully recyclable sandwich components – and to do so on a worldwide level.”

Underbody shield: Freudenberg automotive underbody shields promote sustainable mobility

Arun Venugopal, Strategic R&D Manager at Freudenberg Performance Materials, has developed a lightweight underbody shield made of partially recycled staple fiber and spunbond nonwoven material.

Copyright header photo: Johannes Vogt