Whether for winter coats, carpets or brooms, Freudenberg produces a variety of products that contain recycled PET. Three Business Groups are showing what the old bottles have to offer.

Beverage bottles made of polyethylene terephthalate (PET) still enjoy great popularity: PET’s low weight not only delights consumers – during transport, PET generates lower CO2 emissions than glass bottles do. They are also recyclable. Each year in Germany, 90 percent of all PET bottles are recycled and get a new life as bottles, films and fibers in a wide range of applications. Three Freudenberg Business Groups are leading the way.

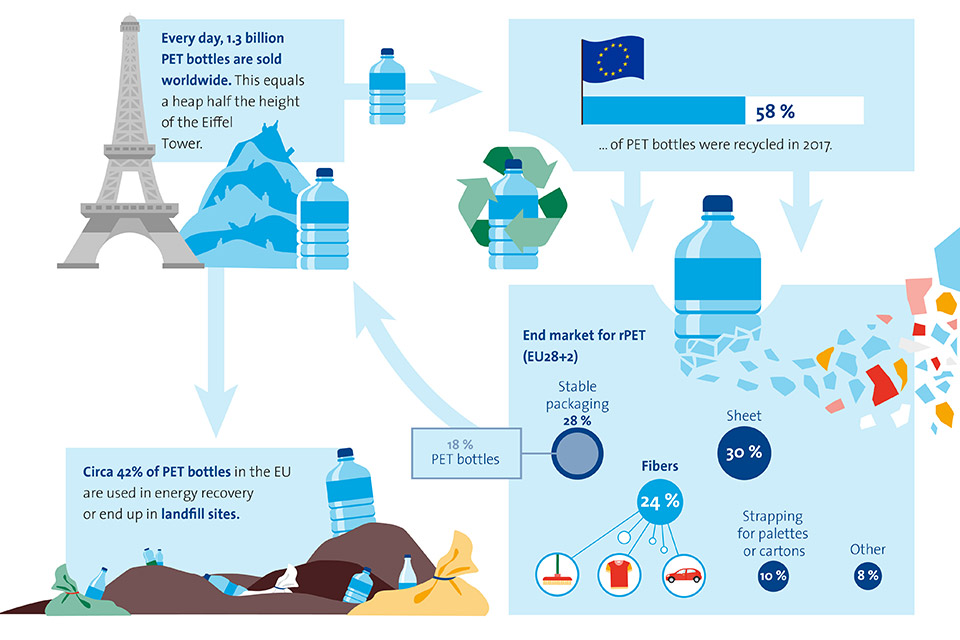

What happen's to a pet bottle?

Sources: EFBW, petcore, Plastic Recyclers Europe, Reuters

Putting bottles on the road

The production of fibers from recycled PET has been part of Tokyo-based Oyama Chemical Company’s core business since 1974. Oyama Chemical is a unit of the Freudenberg Business group Japan Vilene Company, which makes nonwovens that are 97% composed of the recycled fibers. Over the years, the company has built up extensive expertise in the field, especially when it comes to the viscosity, or resistance to flow, of recycled PET.

Over the past few years, employees have continued to develop their process steps: In 2019, Oyama produced small flakes for its own use out of about 370 million PET bottles. They found new life, first as fibers and then as paneling for doors and roofs in car interiors. With this clever reuse of the bottles, a one-way product, Oyama is not only helping to reduce the volume of its waste – it is also cutting down on the consumption of costly raw materials.

But with recycling taking off, prices for recycled PET bottles have recently risen as well, so Oyama shut down its bottle shredding facilities in June 2020. However, given its knowhow in the field, the company can produce fibers from PET chips that are recycled outside the company.

The use of recycled materials is becoming a competitive advantage. (Photo: Osamu Watanabe)

We see major opportunities in the textile and clothing industries, especially in upholstery or as insulation for outdoor use.

Masahiro Amagasa, Oyama’s General Manager

Oyama’s engineers are already working on tomorrow’s products. For example, the Freudenberg company is working hard on other potential applications for recycled PET. Notwithstanding the finite nature of the raw materials, the imagination can run wild when it comes to products based on recycled PET. “We see major opportunities in the textile and clothing industries, especially in upholstery or as insulation for outdoor use,” said Masahiro Amagasa, Oyama’s General Manager.

Trend toward sustainable fashion

With its firm hold on the bottle business, Freudenberg Performance Materials has the edge. The Business Group began recycling used bottles more than 30 years ago. Today, a quarter-century later, the company is one of the most important recyclers of old PET bottles in Europe. For nearly three decades, experts have been using recycled PET in nonwovens that are stitched into the fashion industry’s latest collections worldwide. So the bottle material has long been in demand on the runway. As old bottles find their way into new garments as textile fibers, they are also coming into use in the building industry – another core business of Freudenberg Performance Materials – as membranes or insulation.

A large share of the 2.5 billion PET bottles that the Freudenberg Business Group recycles annually at its plants in Novedrate and Pisticci, Italy, and in Colmar, France, finds new life in many specially developed products.

This allows us to save space and cut down on transportation costs and CO2 emissions.

Sarah Ziem, R&D specialist at Freudenberg Performance Materials

One of the innovations is comfortemp® Fiberball Paddings. The first-ever padding material made of contiguous fiber balls consists entirely of recycled PET, yet it can be processed like traditional padding. It is an innovative and above all sustainable alternative while offering still other advantages: Notwithstanding its ability to breathe, it is robust and easy to care for. That makes comfortemp® a superb choice as an insulating intermediate layer for outdoor and winter fashions. “It was a challenge to use recycled polyester to achieve qualities similar to those of down,” said Sarah Ziem, R&D specialist at Freudenberg Performance Materials. But it paid off: The resilience of comfortemp® offers major advantages. Due to this characteristic, the fiber balls can be vacuum-packed and shipped compactly. “This allows us to save space and cut down on transportation costs and CO2 emissions. That is good for the environment,” Ziem said.

At the Freudenberg facility in Novedrate, Italy, about 3 million PET bottles are processed into polyester nonwovens each day.

Beyond the textile industry, Freudenberg Performance Materials recycles polyester for backing materials for carpet tiles and carpet floors to dampen noise. Bottle material can even be found in the doormats used at the entrances to buildings, among other areas. For the construction sector, Freudenberg experts transform the recycled PET into nonwovens used in noise and heat insulation. So-called bitumen membranes in turn are used on roofs. They waterproof and reinforce roof surfaces, so moisture has no opportunity to penetrate them.

Old bottles, a clean sweep

In addition to their use in cars, fashion and building construction, bottle material can also be found in other everyday products – such as cleaning utensils. For nearly 15 years, Freudenberg Home Cleaning Solutions, has used recycled PET material at its Roncello, Italy, location. At the facility 97 million bottles a year are converted into broom bristles for the Vileda brand. In this process, the bottle material arrives as flakes at Freudenberg Home and Cleaning Solutions. There they are melted into long filaments in an extruder at 280°C. “You can imagine it, in its simplest form, as a spaghetti press,” said David Partiti, R&D Manufacturing Director, EMEA, at Freudenberg Home and Cleaning Solutions in Roncello. “The filaments then go into a water bath for hardening and are stretched to the point where they reach the desired thickness.”

PET flakes are the basis for Vileda brand broom bristles.

The broom bristles have a diameter of less than 1 millimeter, making them as fine as a human hair. Unlike pasta, the filaments made of recycled PET not only have to last a long time. They have to be break-resistant as well.

“At the Roncello site, we are already making our broom bristles with material that is more than 80% recycled PET,” Partiti said. The demand is growing, and Freudenberg Home and Cleaning Solutions is already investigating other products made of recycled PET. For example, in 2020, the Business Group introduced a microfiber cloth wholly constructed of recycled PET from plastic bottles. It can be used to clean household surfaces effectively and sustainably.

But cleaning technology experts do not see PET to be the only material that can be brought back to life. Other recycled plastic materials, such as recycled polypropylene, are being used in new ways such as in the manufacture of buckets.

Together for a better future

Whether for brooms or the latest fashion collection, used bottles have a high added value, as experts from the three Freudenberg Business Groups are demonstrating. They are conserving resources by using about 5 billion PET bottles annually to make new products.

Ensuring the sustainability of products and processes has always been one of the responsibilities that Freudenberg lives and breathes. The use of recycled materials, in particular, is proving to be an efficient use of materials: Resources can be used that otherwise would have to be discarded at great expense. The use of additional materials can also be avoided.

The public’s awareness of sustainable products has continually increased. Environmental protection and climate change mitigation is a fundamental requirement for coping with future challenges. As a technology company, Freudenberg is continually using innovative ideas to expand its portfolio of sustainable products, advancing the use of sustainable resources worldwide.