Materials expertise in the fast lane – improved performance for electric motors

Take a ride with us and learn more about Freudenberg’s innovative solutions in the field of e-mobility – solutions that our Business Groups have shaped over many years with their materials expertise and in-depth know-how.

More and more electric cars are on the road today. And wherever the cars go, a part of Freudenberg goes with them. Solutions for global mobility require constant adaptation and continuous fine tuning. Innovative automotive components that are durable and improve the performance of electric motors are just one example.

The Freudenberg Sealing Technologies (FST) Business Group is our first stop in the series. With innovative thermally conductive electrically insulating (TCEI) materials, the Business Group has developed a suitable material to improve the performance of electric motors. “Our customers kept asking for better materials. So, based on our experience with polymers, we developed a new family of materials specifically tailored to the needs of the electric motor, and which offer superior overall performance,” says Ray Szparagowski, materials developer for high-performance plastics at Freudenberg Sealing Technologies.

How do such materials improve electric motor performance? Thermal management is critical to achieving optimum vehicle efficiency. The temperature of the various components – the electric motor, the power electronics, and the battery – must be kept within an optimum temperature range. At the same time, the material should have effective electrical insulation properties to safely isolate the system. In this situation, the materials must meet a wide range of requirements – such as flammability and adaptability. The right base material is essential.

TCEI materials for improved thermal management

Plastics, in this case polymers, are often the material of choice for electrical components and systems. Such materials offer good electrical resistance but are poor heat conductors compared to metals. For instance, friction losses and the winding of copper wire in electric motors can cause unwanted heat build-up resulting in excessive temperatures.

“Manufacturers can use our TCEI materials to optimize the performance of electric motors through improved thermal management,” says Szparagowski. “The lower operating temperatures in an electric motor have significant benefits. These include a higher electric motor power density, simplified cooling concepts and a longer service life since wire enamel and molding materials tend to degrade at higher operating temperatures.

With more reliable thermal conductivity and improved electrical insulation properties, the TCEI materials offer higher performance in electric motors compared to commercially available materials.

Improved performance with modified plastics

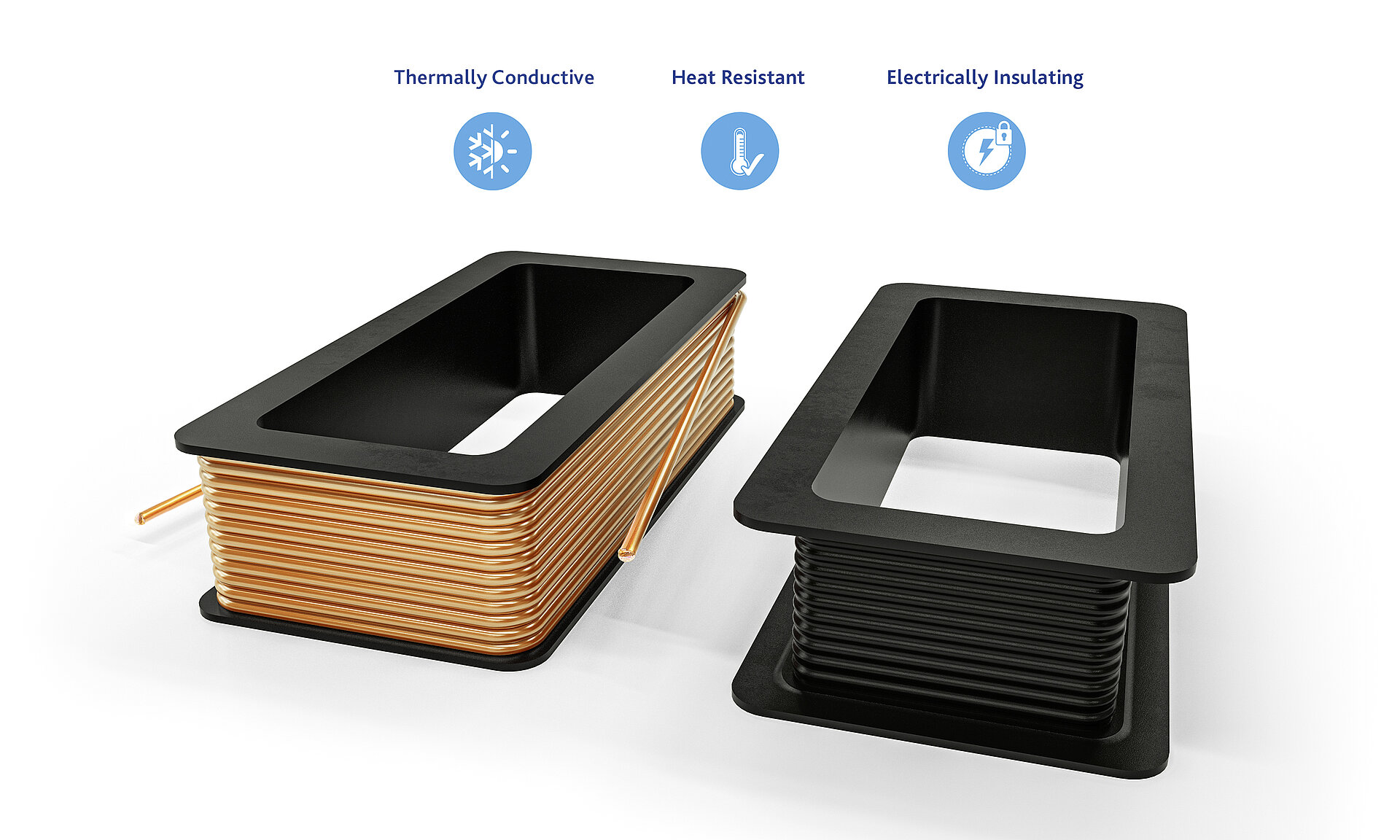

The materials are used, for example, in the manufacture of bobbins for electric motors. The material can be further strengthened by the addition of mineral fillers, which play an important role. With the right filler, the thermal conductivity of modified plastics can be increased many times over that of unfilled polymers. Szparagowski and his team have developed a range of material types that enable Freudenberg to meet specific customer requirements with tailor-made solutions.

With a blend of physical attributes, including electrical, thermal, and material properties, such as elongation and tensile strength, the TCEI materials exhibit superior thermal conductivity and improved electrical insulation properties compared to commercially available materials. The higher filler content results in a stiffer material that can be molded into thinner cross-sections, resulting in lower material consumption at the same time. The slimmer design of the bobbins provides more space for the copper wire, which can increase motor performance. Bobbins also protect the windings from damage and vibration during assembly and operation.

Innovation drives progress

With the innovation of such novel materials, Freudenberg is applying its expertise precisely where its customers need it. The further development of thermally conductive, electrically insulating materials opens up new applications in the field of e-mobility. But the materials presented here are not the only ones playing a key role in a more sustainable automotive industry. Stay tuned for the next stop in our e-mobility series!