Good for the environment, good for the company

A state-of-the-art seal that reduces methane emissions to zero: Our journey through Freudenberg’s product innovations takes us to the EagleBurgmann Business Group – our third stop – where there is another invisible yet indispensable innovation waiting to be discovered. EagleBurgmann’s seal reduces methane emissions to zero and, in so doing, offers a solution that is both good for the environment and good for the company.

Global warming is having a visible effect on our planet. Every one of us – whether as an individual or as a company – can take action to help tackle and slow down climate change. EagleBurgmann’s innovation focuses on the greenhouse gas, methane. Once released into the atmosphere, methane contributes to global warming and is harmful to the environment. Along with livestock farming and landfills, such methane emissions are also due to leakage from natural gas pipelines, for instance.

The greenhouse gas methane (CH4) is the main component of natural gas. When it is used to generate energy, it produces significantly less carbon dioxide (CO2) than other fossil fuels. However, if methane enters the atmosphere directly – for example through leakage – it is much more harmful. Over a period of 20 years, the impact it has on the atmosphere is 84 times higher than CO2.

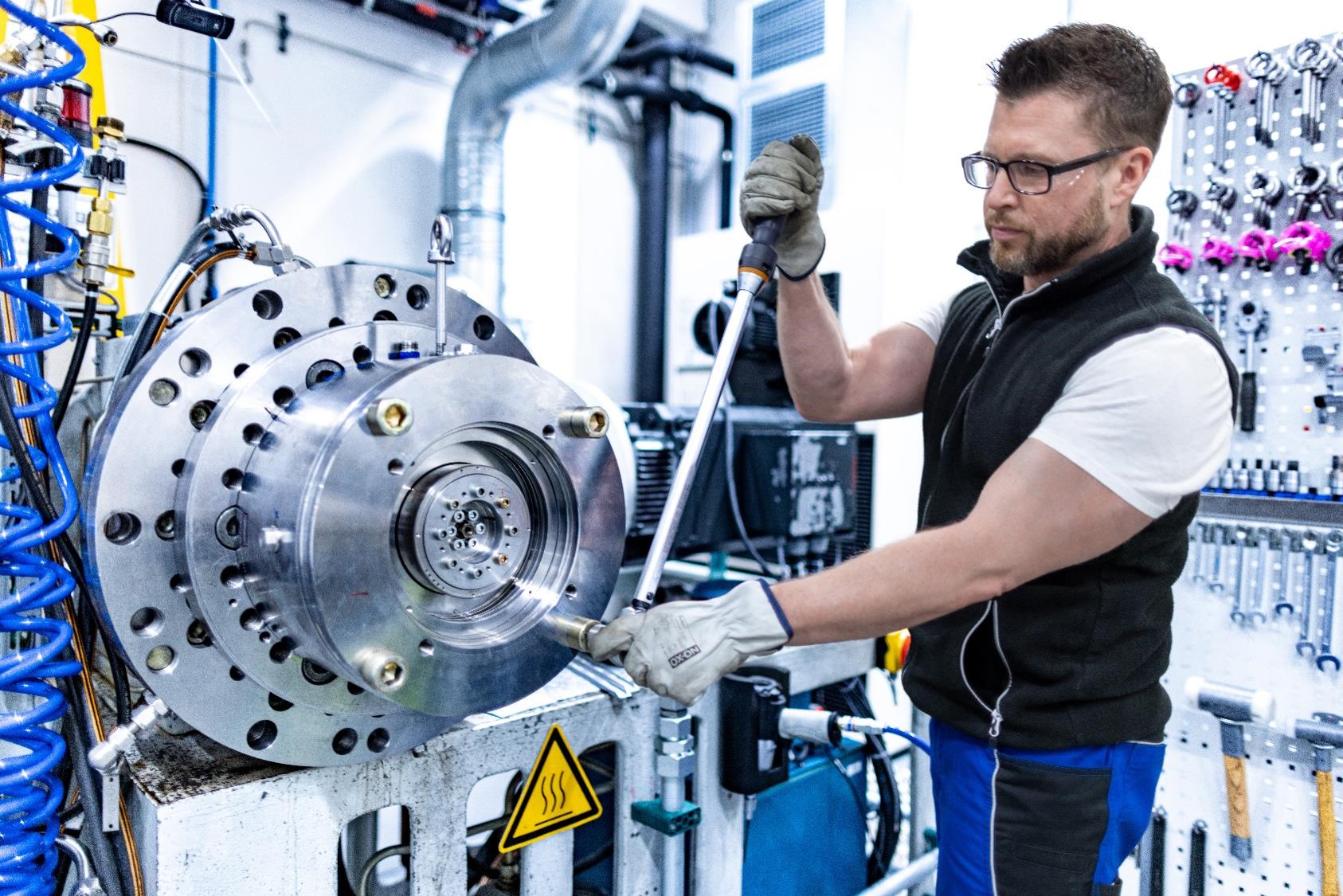

EagleBurgmann’s CobaDGS® is the world’s first compressor seal that reduces fugitive methane emissions to zero. Until now, conventional seals have been known either for their climate-friendliness or their functional reliability at high pressure and high temperatures. This meant that, in the past, manufacturers and customers of turbo compressors have had to settle for a compromise. But the CobaDGS® now combines both properties and represents a climate-friendly sealing solution for turbo compressors in the higher-pressure range.

The EagleBurgmann Business Group places the customer at the heart of its operations and focuses on the cost/benefit aspects of production. Sustainability and cost-effectiveness go hand in hand: Not only is the Business Group’s seal for turbo compressors a pioneering solution for the environment, it also truly makes good business sense.

EagleBurgmann’s CobaDGS®: The climate-friendly sealing solution for turbo compressors in the higher-pressure range

A solution that is good for the environment and good for the company: At EagleBurgmann, sustainability and good business sense go hand in hand

Emission reduction in comparison:

A mid-range car emits about 120 grams of CO2 per kilometer (Europe). Assuming a car drives 10,000 kilometers a year, this adds up to 1.2 tons of CO2. The savings that can be achieved with a CobaDGS® are therefore equivalent to the emissions of 10,452 cars driven each year.

About EagleBurgmann

EagleBurgmann – at the leading edge of industrial sealing technology. Our products are used wherever safety and reliability count: in the industries of oil & gas, refineries, petrochemicals, chemicals, pharmaceuticals, food, power, water and many more. About 6,000 employees contribute their ideas, solutions, and dedication every day to ensure that customers around the globe can rely on our seals. With our modular TotalSealCare Service, we emphasize our strong customer orientation and offer custom-tailored services for every need.

Our next stop:

Capol of the Freudenberg Chemical Specialities Business Group. Join us again @ Freudenberg Magazine Online and find out about an invisible innovation for granulated sugar coating.